Cas NO.143-33-9

English alias:NACN

formula:NACN

Molecular weight:49.01 g/mole

Structure chart:

Main product for Gold Cyanide Heap Leaching Process

.jpg)

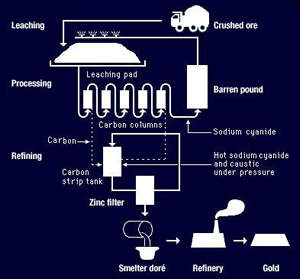

Gold Cyanide Heap Leaching Process

The successful application of heap leaching to the extraction of gold from low-grade deposits has been one of the main factors in higher output since the 1970s, especially in the United States. It is a low cost process that extracts a soluble precious metal or copper compound by dissolving the metal content from the crushed ore.

|

Spraying cyanide on leach pads at the Zortman-Landusky mine in Montana /(Credit: Timothy Green)/

Ore is heaped onto open-air leach pads with a base of asphalt or impervious plastic sheeting. A sprinkler system is then laid along the top of the ore pile through which a solution of dilute cyanide is sprayed. The cyanide percolates down through the heap for several weeks, leaching out the gold. This solution, now enriched with gold, drains off the bottom of the pad into what is known as the 'pregnant pond', from which it is pumped to the recovery plant.

|

|

|

Heap Leaching: extraction of gold using heap leaching and carbon recovery

Cyanide has a natural affinity for gold , which dissolves in it just as sugar would in a hot drink. Cyanidation has been the principal method of extracting gold from ore since the development of the MacArthur-Forrest Process in 1887, which proved crucial in the development of the South African gold mining industry. The perfection of the cyanide process largely replaced amalgamation with mercury that had previously been the main method of extracting gold from ore. Cyanidation has also become crucial since 1970 in gold recovery from low grade deposits through heap leaching . It should be noted that cyanide is extremely toxic and must be handled with special care.

|

|

| Heap leaching of gold was pioneered in the United States in 1973 at Placer Development's Cortez open pit in Nevada and proved on a larger scale at Pegasus Gold's Zortman Landusky mine in Montana. Although it is low cost, recovery rates average only sixty to seventy per cent, significantly less than with conventional milling. But it has enabled low-grade ores, which otherwise might not be economically viable, to be processed. In the United States, where heap leaching is used most extensively, half of all production is won by this method. |

|